By Eric Danville

Emerald Metrics Mixes Software and Hardware to Help You (and Your Business) Grow

Some of the most enduring propaganda images from the 1980s-era War on Drugs come from grainy, almost psychedelic color footage, usually shot from a helicopter or airplane, showing a row of houses. Most of the buildings are dark, but one has the tell-tale glow of a large amount of concentrated, constant heat: the sure sign of a clandestine marijuana growing operation. A more updated application borne of this electronic detection technology—but relying on the refraction of light instead of the detection of heat—is the concept behind Emerald Metrics (EM), which it to increase yield instead of busting growers.

Some of the most enduring propaganda images from the 1980s-era War on Drugs come from grainy, almost psychedelic color footage, usually shot from a helicopter or airplane, showing a row of houses. Most of the buildings are dark, but one has the tell-tale glow of a large amount of concentrated, constant heat: the sure sign of a clandestine marijuana growing operation. A more updated application borne of this electronic detection technology—but relying on the refraction of light instead of the detection of heat—is the concept behind Emerald Metrics (EM), which it to increase yield instead of busting growers.

The use of high-tech equipment to help the farming industry—a concept called “precision agriculture”—isn’t exactly new. John Deere helped pioneer it in the 1990s with GPS tech systems that helped to more efficiently guide farmers’ tractors while laying seed to avoid wasting time, energy and resources. Other aspects of precision agriculture can be traced back to the 1960s. But EM’s adoption and application of this approach to farming is not only novel, it’s increasingly crucial in the fast-paced world of commercial cannabis cultivation.

“The technology has evolved immensely since the War on Drugs,” says Rob McCorkle, who retired from a twenty-year career with the Las Vegas Police Department as a lieutenant commander working SWAT and anti-terrorism details before taking this decidedly different career path. “They were using forward-looking infrared to find heat signatures. But they also used, and today still use, multispectral cameras to find methamphetamine dumps.” McCorkle, who also holds degrees in criminology and criminal justice administration, describes just how precise the technology can be: “We worked overseas in Afghanistan and Iraq finding bomb makers planting IEDs. We could identify from 10,000 feet in the air if they had bomb-making chemicals like gunpowder, TNT or C4 residue on their bodies. We do the same thing now with cannabis, just at different levels.”

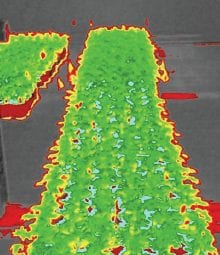

Through the use of their own office-based hyperspectral cameras and handheld spectrometers, plus the installation of multispectral cameras in their clients’ grow facilities, Emerald Metrics can determine whether a grower’s crop is healthy or in danger of anything, from mold and moisture to residual pesticides to insect infestation, with hardware that “looks at 125 different layers of light to determine the spectrum and how the biologic reflects light, based on algorithms we’ve created.” Based on what they discover, their clients are able to decide whether a plant is ready for sale to the public (or to other growers in the form of clones) or whether the plant is no longer viable and should be destroyed.

Through the use of their own office-based hyperspectral cameras and handheld spectrometers, plus the installation of multispectral cameras in their clients’ grow facilities, Emerald Metrics can determine whether a grower’s crop is healthy or in danger of anything, from mold and moisture to residual pesticides to insect infestation, with hardware that “looks at 125 different layers of light to determine the spectrum and how the biologic reflects light, based on algorithms we’ve created.” Based on what they discover, their clients are able to decide whether a plant is ready for sale to the public (or to other growers in the form of clones) or whether the plant is no longer viable and should be destroyed.

“Our operation makes sure that every plant you’re moving forward at propagation is healthy,” says McCorkle. “The industry accepts anywhere from a ten to twenty percent reduction in yield due to unhealthy clones and teens, because you can’t really see how healthy the plants are. The plants may look healthy to the human eye, but they aren’t necessarily.” EM’s system not only can ensure that a clone is up to 90 percent healthy, it offers the exact images of the healthy plants for its customers to pass along after sale as proof of the product’s quality.

Such pictures are taken of a grow company’s product and processed using a combination of Amazon’ web-based Artificial Intelligence (AI) and EM’s own original algorithms and software. “We’re looking for specific biologic signatures that we have in the background, and the camera then uploads those images by the pixels to our servers. Those servers go through the algorithms and determine whether each pixel of an image contains any anomaly or unhealthy plant tissue.” That information is sent back to EM and routed to a dashboard system, which is then accessed by the grower remotely or sent back to the grower client’s own electronic set-up.

Such pictures are taken of a grow company’s product and processed using a combination of Amazon’ web-based Artificial Intelligence (AI) and EM’s own original algorithms and software. “We’re looking for specific biologic signatures that we have in the background, and the camera then uploads those images by the pixels to our servers. Those servers go through the algorithms and determine whether each pixel of an image contains any anomaly or unhealthy plant tissue.” That information is sent back to EM and routed to a dashboard system, which is then accessed by the grower remotely or sent back to the grower client’s own electronic set-up.

“Some of our clients use the health table just to see whether the tissue of the plant is healthy or not,” he says. The process can start, obviously, at the cloning stage. “Almost all of our clients start with our cloning tables, when they’re just looking toward moving forward the best clones possible into propagation, so they have the greatest potential for a 100 percent yield. We look through the molecular structure of the plant, how it’s refracting light, how much energy it’s uptaking and outputting, and we can tell you if you’re clones, vegetative and flowering plants are healthy or not.”

McCorkle uses a particularly deadly enemy of cannabis farmers as an example. “Powdery mildew refracts light three different ways: pre-spore, spore and at depth. We can see powdery mildew on the plant before it spores, that is, before it turns white. Once it spores, it’s in the air, and at that point it’s spreading. We can also image plants and tell you if there are spider mites that are stifling the tissue underneath the plant’s leaves. Right now, the only way to find spider mites is by lifting up the plant leaves and looking underneath. We can tell you if they’re eating the tissue by imaging the top of the plant, not the bottom, so you already know which plants to go look at instead of spending days digging through your grow operation.”

After all this information is gathered, Emerald Metrics relays it to growers by means of a “CannaIntelligence” dashboard that can be used remotely through EM’s iOS or Android-based apps, a dedicated desktop or laptop computer system or by growers who have their own sophisticated grow operations. “A lot of our growers already have dashboards tied into their water, humidity or CO2 sensors, so we can integrate our data into their dashboards, or they can migrate their data out to our dashboard.” Growers can then generate an anomaly report that shows the existence of irregularities that can affect their plants, and then can act accordingly.

After all this information is gathered, Emerald Metrics relays it to growers by means of a “CannaIntelligence” dashboard that can be used remotely through EM’s iOS or Android-based apps, a dedicated desktop or laptop computer system or by growers who have their own sophisticated grow operations. “A lot of our growers already have dashboards tied into their water, humidity or CO2 sensors, so we can integrate our data into their dashboards, or they can migrate their data out to our dashboard.” Growers can then generate an anomaly report that shows the existence of irregularities that can affect their plants, and then can act accordingly.

If this sounds complicated, well, it is. But the end result is much simpler. The marriage of Emerald Metrics’s high-tech visual and analytic technology with the hands-on, practical advancements in marijuana cultivation over the decades can weed out destructive elements from your harvest, giving you a higher yield and, of course, a higher return on your investment. And it doesn’t take a genius to understand that.

For more information, log on to www.emeraldmetrics.com.

Leave a Reply